The LIGA-process (German for: lithography, electroplating and molding) is well suited to produce high aspect ratio micro structures in polymers or in metal. The process allows making micro structures as high as a few millimetres with aspect ratios up to more than 100. The structures have parallel side walls with a small roughness in the range of 10 nm. The geometry of the structures can be chosen via the electron beam writing of the necessary X-ray absorber mask. The advantage of the LIGA-process for making refractive X-ray lenses is, that hundreds of well aligned, refracting micro structures with smooth side walls and small radii of curvature in the range of a few micrometres can be made in one step. Refractive X-ray lenses are made in SU-8, a highly sensitive negative resist. The main advantages of SU-8 are its X-ray transparency and its stability against radiation damage, so SU-8-lenses can be used for a long time. For photon energies above about 40 keV CRLs made in Nickel can be used [Naz 2007].

These types of refractive X-ray lenses can be distinguished:

| Fresnel lenses | Mosaic lenses | Clessidra and prism lenses |

Parabolic compound refractive lenses (CRLs) with line or point focus

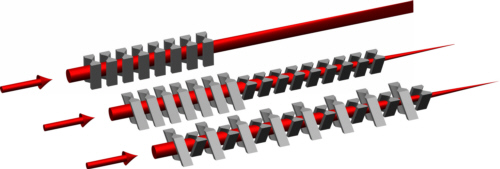

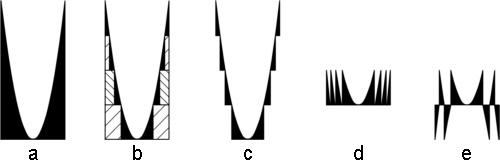

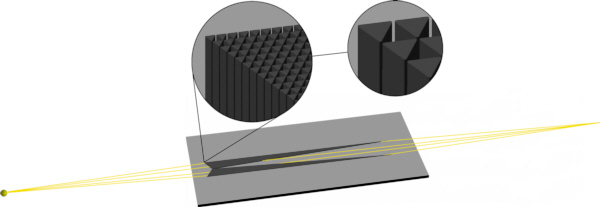

To avoid spherical aberration, the refracting surfaces have to be parabolic to focus X-rays parallel to the optical axis to a line or point focus. For lenses with a line focus the micro structures are made perpendicular to the substrate (fig. 1, top). For point focus lenses, two sets of lenses with a line focus are realized on one substrate, tilted to 45° to the substrate (fig. 1, middle and bottom).

Fig. 1: Focusing X-rays using refractive X-ray optics: line focus (top), point focus (below)

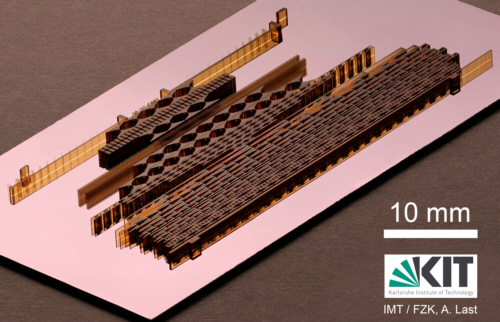

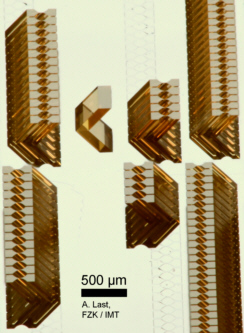

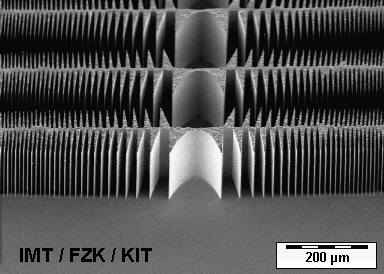

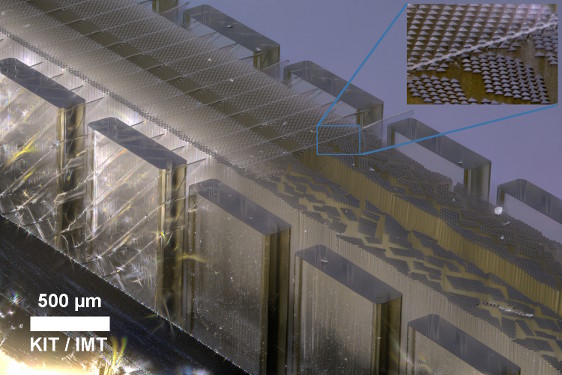

A real lens plate produced at the Institute of Microstructure Technology (IMT) at the Karlsruhe Institute of Technology (KIT-IMT) with 25 different line focus lenses is shown in fig. 2, [Naz 2004]. The number of focusing elements in a single lens varies from 3 to 128.

Fig. 2: Example of a substrate with 25 refractive X-ray lenses made by LIGA process providing a line focus (left  ) and a detail of the lens elements and their mirror image (right, ©01)

) and a detail of the lens elements and their mirror image (right, ©01)

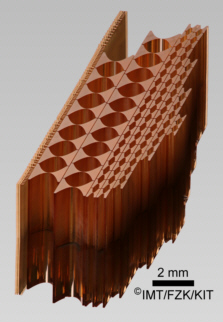

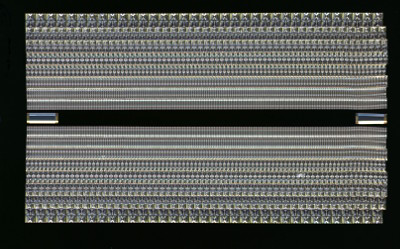

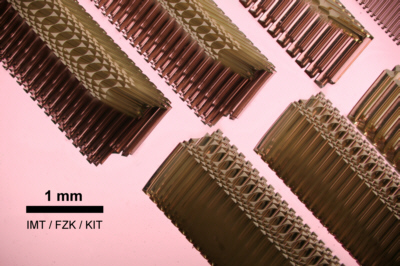

Fig. 3 is a macro photograph of an array of 16 IMT component refractive X-ray lenses with point focus on a silicon substrate. Each row has got a different number of single lens elements with different radii of curvature. When a special focal length is required for a special photon energy, the focal length of each row can be adapted by removing the adequate number of lens elements. The vertical and horizontal focal length can be adapted separately. The focal length can only be prolonged and of course the removing of the lens elements is irreversible. The removal is done manually by knocking over dispensable lens elements using a needle and then blowing them away using compressed nitrogen gas (fig. 4). Alignment structures are situated in the centre of the lens plate. The image resolution in full field microscopy with these lenses in 2017 reached 180 nm per line and space at an photon energy of 30 keV.

Fig. 3: Example of many crossed refractive X-ray lenses made by LIGA process providing a point focus (left side  ) and detail with removed lens elements (right side, ©01)

) and detail with removed lens elements (right side, ©01)

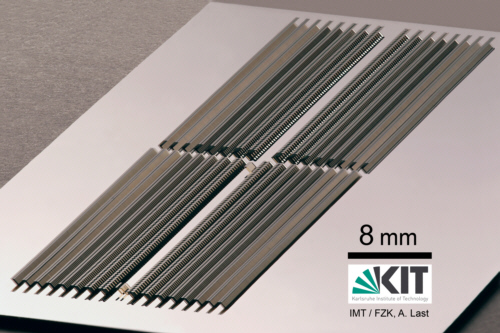

Fig. 4: Process of manually removing elements not needed in a 16 CRL lens plate made by LIGA process, ©01

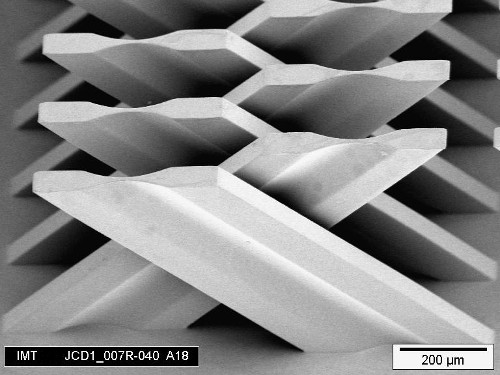

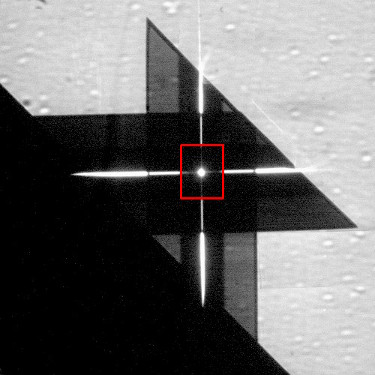

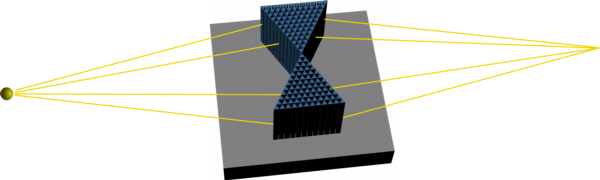

Figure 5 shows a point focus CRL made via deep X-ray lithography by a double exposure under ±45° and its detector image with the point focus.The useable aperture of the CRL is located in the area, where the two parabolas are crossed (marked red).

Fig. 5: CRL with point focus exposed under 45° (left) and point focus of a lens in the beam; the useable aperture is marked red (right), ©01

As the optical path length through the lens material for the border rays is increasing proportional to the square of the lens aperture for parabolic lens profiles, the maximum useful aperture is limited to a few hundred micro meters by the absorption of the material. The effect of refraction takes place at the surfaces of the lens elements. So larger apertures can be realized, when material from the bulk areas of the lens elements is removed as in so called Fresnel-lenses (fig. 6).

Fig. 6: The generation of Fresnel-lenses: a) parabolic profile, b+c) material removable without changing the optical properties a lot, d) shifting the remaining elements to form a more compact design, e) flipping over every second element to form a geometry more easily accessible to the solvents (©01)

Fresnel-micro lenses are technically difficult to realize as the thin triangular wall elements (fig. 7) tend to deform or show edge rounding. These effects reduce the effectivity of the lens and again limit the maximum usable lens aperture.

Fig. 7: Fresnel-lens with line focus, electroplated in nickel for high energy light (©01)

Another concept for large aperture lenses are so called mosaic lenses, where lens material is removed in a way, that small quasi-triangular parts of the parabolic lens profile remain (fig. 8).

Fig. 8: Large aperture crossed mosaic lenses with point focus; as the silicon substrate is strongly reflecting, the mirror image of the lens elements is visible (©01)

Clessidra-lenses and refractive prism lenses

Also so called Clessidra-lenses allow for large lens apertures (fig. 9, [Jar 2008]). The outer footprint of these lenses reminds of an hour glass. The italian word for hour glass, "Clessidra", has given the name of the lenses. Near the optical axis the X-rays hit just a few refracting prisms and are redirected to the focus point. The more distant from the optical axis the X-rays hit the lens, the more prisms they will encounter and the larger is the change of the direction of the ray.

Fig. 9: Sketch of a Clessidra lens

The largest lens apertures with the highest average transparency can be achieved with X-ray refractive prism lenses (XPL) [Sim 2008]. These lenses consist of tens of thousands of triangular prisms. The prisms are arranged in a different geometry than in a Clessidra lens to achieve the maximum throughput (fig. 10). At each prism the direction of the rays is redirected by a small angle resulting in an approximately circular path of the rays in the areas filled with prisms. Each prism has to be positioned exactly on the curved path of the light through the lens.

Fig. 10: Sketch of a refractive prism lens and details of the prism areas

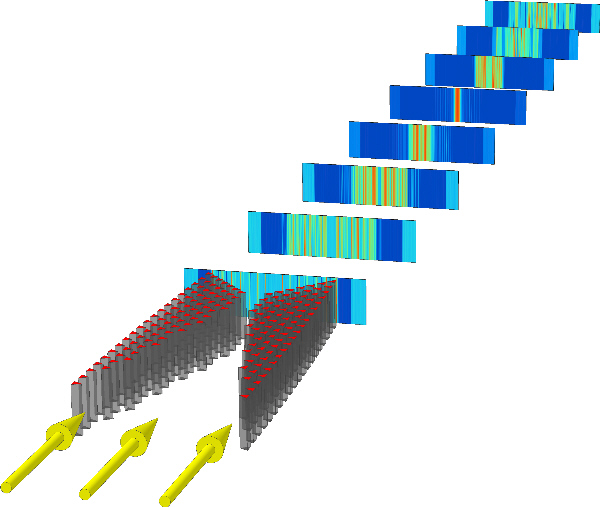

Figure 11 shows the simulated intensity distribution in different distances behind an XPL consisting of only 170 prisms. The width of the high intensity focal line (red) in the 5th plane behind the lens corresponds approximately to the size of a single prism. The spurious intensity lines next to the focal line result from light entering the lens between two prism rows or being misguided by total external reflection at the prism surfaces most distant to the optical axis.The pale blue left and right borders of the planes result from light that has not hit the lens. The colour stands for the intensity in the corresponding plane, with no lens in the optical path.

Fig. 11: Simulated intensity distribution behind an X- ray refractive prism lens

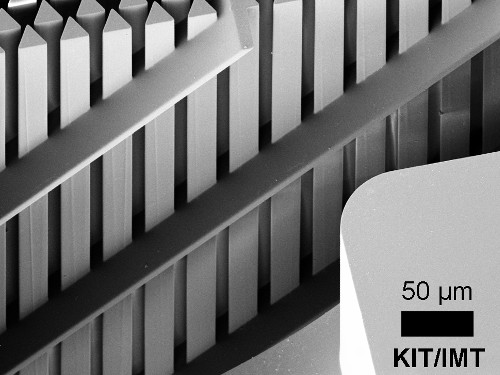

To get a point focussing prism lens, two lithographically processed line focus prism lenses are tilted by 90° around the optical axis and positioned one behind the other. The entrance aperture can only be fully used when the line focus lenses have squadred apertures. To get for example an aperture of 1 mm x 1m, the prisms have to be 1 mm high. Prisms with 20 µm edge length can easily be processed. Such prisms then have an aspect ratio of 1:50. As the development of the microstructures is a wet process the structures have to be dryed. While drying, capillary forces between the prisms deform the prisms, resulting in a low quality optics. This effect can be reduced by freeze drying the structures. Introducing supporting planes further improves the structural quality. The planes are exposed under 45° (Fig. 12). They support the prismsat both sides between neighbour planes (except above the topmost plane), so the prisms can stand the capillary forces.

Fig. 12: Line focus prism lens with 20 µm prisms and 45° supporting planes. Left photograph: left half of the image with supporting planes and nicely arranged prisms, right halfwithout planes showing misaligned prisms. Right SEM-image of the supporting planes (©01)

| [Jar 2008] | W. Jark, F. Pérennès, M. Matteucci, L. De Caro, CLESSIDRA: focusing hard x-rays efficiently with small prism arrays, Modern Developments in X-Ray and Neutron Optics, Springer Series in Optical Sciences , vol. 137, pp. 331-351, Springer (ISBN: 978-3-540-74560-0), 2008 |

| [Naz 2007] | V. Nazmov, E. Reznikova, A. Last, J. Mohr; V. Saile, M. DiMichiel, J. Göttert, Crossed planar X-ray lenses made from nickel for X-ray micro focusing and imaging applications, Nuclear Instruments and Methods in Physics Research A, 39306, pp. 120-122, DOI: 10.1016/j.nima.2007.08.076, 582, 2007 |

| [Naz 2004] | V. Nazmov, E. Reznikova, A. Somogyi, J. Mohr, V. Saile, Planar sets of cross x-ray refractive lenses from SU-8 polymer, Proceedings of SPIE, vol. 5539, pp. 235-243, 2004 |

| [Sim 2008] | M. Simon, E. Reznikova, V. Nazmov, A. Last, W. Jark, X-ray prism lenses with large apertures, Proc. SPIE, vol. 7077, 70771Q, DOI: 10.1117/12.795423, 2008 |